Chemical Products

- Home

- Products

Showing chemicals & compounds results

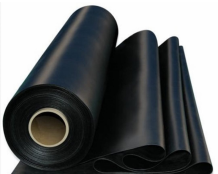

PE-Polyethylene Fillers

B1 PE Fillers

It is a common substance found in rocks such as calcite, aragonite and minerals (especially such as limestone, which contains these two minerals). PE filler is a mixture of calcium carbonate with polyethylene. It is often used in the production of films and products obtained by injection for lowering the cost of final products and enhancing the quality.

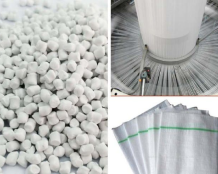

PP-Polypropylene Fillers

B2 PP Fillers

Polypropylene is a thermoplastic polymer resin that can be easily combined with other composites. The PP Filler additives is extremely popular among manufacturing engineers, particularly for injection molding, Yarn, Raffia because it is exceptionally durable and suitable for a wide variety of use-cases. PP Filler materials can affect the tensile strength, toughness, heat resistance, color, clarity, and will improve the property.

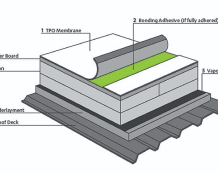

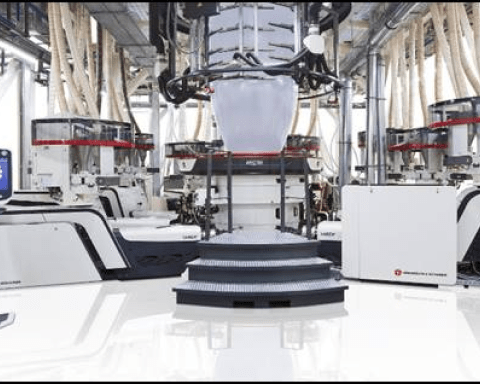

Engineering Compounds

Engineering polymer compounds have various applications in the field of food packaging, automotive industries, home appliances, pipes, fittings, (etc...) due to having better Impact properties, flexibility, rigidity, creep, thermal resistance, flame retardancy and many other characteristics than ordinary plastics.

Engineering polymer compounds are materials that are reinforced by other polymers or mineral additives, including glass fibers or mineral powders such as talc and mica powder or a variety of rubbers. These materials have superior technical specifications compared to ordinary plastics.

A62 ABS/PC

This thermoplastic engineering compound is used for the following advantages; High impact strength, even at low temperatures. Good heat resistance. High stiffness. Easy processing. Low overall shrinkage and high dimensional accuracy.

A69 POP/POE

The unique molecular of POP and POE provides films, fibres, sheet and moulded parts with an outstanding combination of excellent optics, sealing and hot tack performance, plus elasticity, flexibility, softness and compatibility in blends.

Calcium Carbonate

It is a common substance found in rocks as the minerals calcite and aragonite It has a white/off white color and is one of the abundant materials on Earth

1) Used in the construction industry and less in the medical

industry as a calcium supplement.

2) Heavily used in the polymer industries including

plastics, paints, adhesives, household cleaning among

others

3) Employed in the plastics industry for enhancing

efficiency, product thermo-mechanical-chemical properties,

processing, cost, color among others.

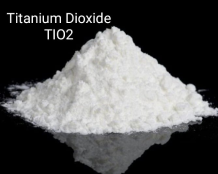

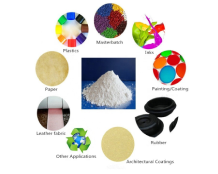

Titanium dioxide

It is a crystalline solid white in colour which is insoluble in water and alcohol but soluble in concentrated acids. It is odourless. Titanium dioxide is an alkaline, divalent metal. It is non-toxic and safe for medical use.

Titanium dioxide (TiO2) is a fine white powder or dust that occurs naturally. It was first intentionally produced for use as a white pigment in 1923. It is naturally opaque and bright, which makes it useful paints, catalytic coatings, plastics, paper, pharmaceuticals and sunscreen, some lesser-known applications include packaging and commercial printing inks. TiO 2 can also be found in cosmetics, toothpastes, ceramics, rubber, textiles, and food.

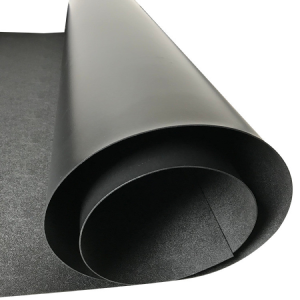

Fluoropolymers

Fluoropolymers are a family of high-performance plastics characterized by their strong carbon-fluorine (C-F) bonds. This unique atomic structure imparts a range of desirable properties, such as chemical resistance, thermal stability, and electrical insulation.

Fluoropolymers are used to protect and insulate wires in order to prevent overheating and potential fires. Fluoropolymers have unmatched chemical and temperature resistance which is why they're used in products like cars, planes, transportation, chemical process, resource recovery, electronics, semiconductor, aerospace and textile industries, masterbatch flame retardant. The materials of choice for products and systems that work in tough environments and require high reliability.

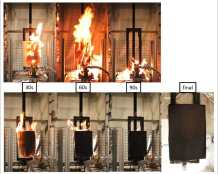

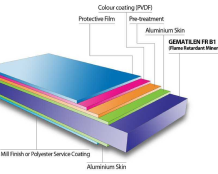

Magnesium hydroxide

It is a white powder with specific gravity of 2.36. , very slightly soluble in water; decomposing at 350°C. Magnesium Hydroxide is an inert filler, flame retardant and smoke suppressant for plastics,synthetic rubber, reinforced polyesters, phenolics and urethane foam.

Magnesium hydroxide is an effective flame retardant and smoke suppressant for use in low-smoke, fire retardant plastic compounds for a variety of applications; Aluminum panel, isolation foam, building and construction, Automotive.

Talc

Talc is a soft mineral and easily micronizable into fine particle sizes. Subsequently, these fine particles of Talc efficiently fill up inter-particular spaces within polymer compounds. This, in turn, increases the stiffness and impact strength of plastics and polymers.

Talc powder for the plastic and extrusion industry is an excellent filler due to its blending characteristics, thermal and electrical resistance. Moreover, talcum powder for the plastic filler is chemically inert and provides a smooth feel to the plastic surface.

Calcium stearate

Calcium stearate is primarily used as an acid scavenger, release agent and lubricant in the plastics industry, for waterproofing in construction, and as an anti-caking additive in pharmaceuticals and cosmetics.

Calcium stearate, an internal lubricant which reduces friction between polymer resin during processing, is commonly used in plasticized PVC which is melt processed External lubricants, which are essential in rigid PVC compounds, are not always necessary when plasticizers are present. It's heavily in use for all plastic operation as lubricant and enhancement of quality.

Antioxidants

Antioxidants are added to plastics to inhibit degradation caused by thermo-mechanical or thermo-oxidative conditions. Antioxidants extend a product's life, enhance the appearance and maintain its strength, stiffness and flexibility.

The importance of antioxidant additives usage in all the plastics industry. (Injection, blow, blown, cast, thermo etc... ) antioxidants polymer additives are essential because they help prevent a process called oxidation. By doing so, they are able to stabilize the plastic products' qualities and slow degradation processes.

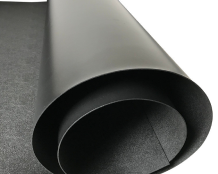

Carbon Black Pigments

Carbon black pigments have a number of advantages compared with other inorganic black pigments and with black organic colorants. Hiding power, color stability, solvent resistance, acid and alkali resistance as well as thermal stability are excellent good properties that are not achieved from other blacks.

Carbon black pigments has many applications in plastics. It's used in compounds with other plastic carriers as colorant black masterbatch in some cases is used directly as is. Application for the usage of MB black is at all plastic operations.