Sustainsble Product Detail

- Home

- Sustainsble Product

Showing sustainable product results

C1-LLDPE Recycling

LLDPE Recycling processed in state of art mechanical recycling, where the material is melted down at minimal temperature for maintain the properties of the product and turned into new products; Natural, White, Colored light grey to black.

- LLDPE Recycling, produced from sorted segregated by products to add value and reduction in usage of the new sources. In use for Blow, Blown, Cast, Injection and thermo-forming applications.

C2-HDPE Recycling

HDPE Recycling processed in state of art mechanical recycling, where the material is melted down at minimal temperature to maintain the properties of the product and turned into new products; Natural, White, Colored light grey to black.

HDPE Recycling, produced from sorted segregated by products to add value and reduction in usage of the new sources. In use for Blow, Blown, Cast, PIpe, Injection and thermo-forming applications.

C3-LDPE

LDPE Recycling processed in state of art mechanical recycling, where the material is melted down at minimal temperature for maintain the properties of the product and turned into new products; Natural, White, Colored light grey to black.

LDPE Recycling, produced from sorted segregated by products to add value and reduction in usage of the new sources. In use for Blow, Blown, Cast, Injection and thermo-forming applications.

D1-HPP Homo Polypropylene Recycling

Similar to virgin plastic, recycled PP Homo has valuable material properties, like high flexural and impact strength, good fatigue resistance, and high chemical resistance against most organic solvents, many acids, and bases at room temperature. HPP usage is considered as sustainable progress and applied to 5R's.

Homo Polypropylene parts can be 100% recycled for various useful purposes. A market for recycled PP (rPP) exists in an extensive range of products such as automotive applications, buckets, caps and closures, garden furniture, pallets, pipes, and more.

D2-COPO Copolymer Propylene

Recycle COPO polypropylene material is so adaptable, PP can be recycled into many different types of products, including fibers for clothing, industrial materials, kitchenware and more.

Recycle COPO polypropylene id useful in parts that require good impact resistance. Impact copolymers are mainly used in packaging, houseware, film, and pipe applications. They are also used in the automotive and electrical segments.

E1-PET Bottle Recycling

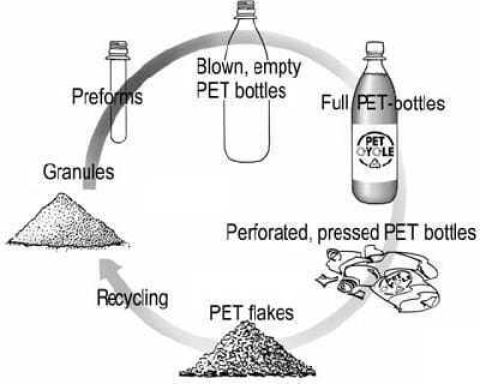

Recycled PET Bottle to bottle collected, sorted, crushed, flaked and washed heavily in several phases before being heated and recycled. This is then spun into recycled bottle production of 100% sustainable products.

PET preform, to bottles and could be used for other low end applications

E2-General PET Recycling

Recycled General PET is flaked and washed before being heated and stretched into fiber. This is then spun into recycled polyester yarn and used to make fabrics that can be used in seat belts, bags, carpets, roofing insulation and even clothing.

Recycled General PET may be used for many applications such as food packaging and non-food packaging, automotive parts, technical and textile fibres such as clothing, carpets and bedding. Also the building industry is making use of PET regrind for example as isolation.